From BOM to Build Mastering the Lifecycle Hardware

5 mins read

Published Jan 19, 2026

For controls engineers and system integrators, the "hardware" is never just parts on a shelf. It is the physical manifestation of months of design, thousands of dollars in capital, and the critical path to a successful FAT (Factory Acceptance Test).

Yet, too many firms rely on a disjointed mix of Excel spreadsheets, frantic email chains, and whiteboard notes to track these assets. When a $5,000 PLC card goes missing or a VFD sits in "Received" but never makes it to "Staged," it isn't just an annoyance—it is a direct hit to your project’s profitability.

Here is why granular tracking of control panel hardware—from the moment it’s specified to the moment it’s wired—is essential for project management and financial health.

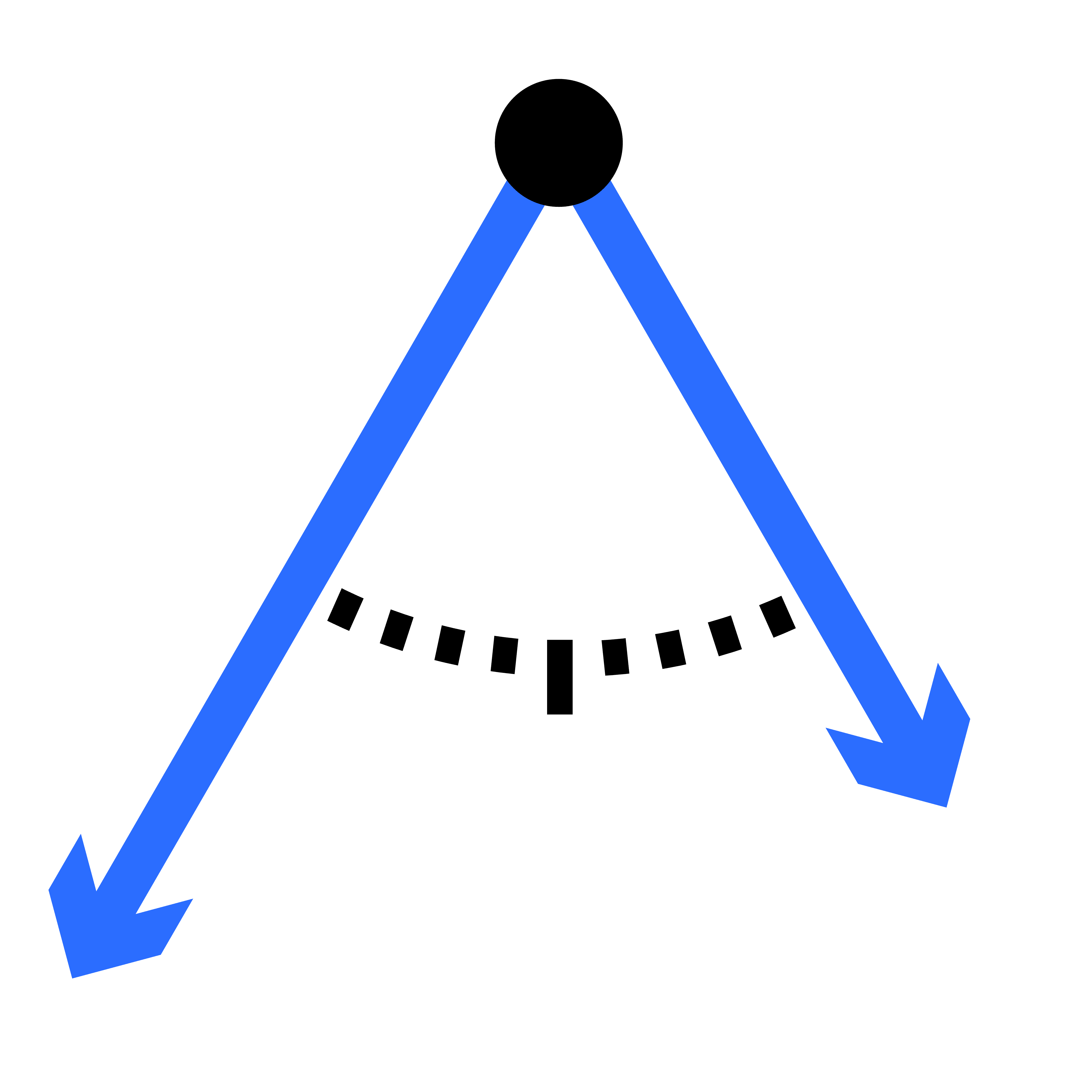

The Lifecycle of a Part: A Phased Breakdown

To manage a project effectively, you must know exactly where every component lives in its lifecycle.

1. The Planning Phase (The BOM)

Before a single dollar is spent, the hardware exists as a line item on the Bill of Materials (BOM).

The Reality: This is where scope creep begins. Engineers specify parts based on initial designs, but as the P&ID evolves, so does the hardware list.

The Goal: Accurate estimating. Tracking here ensures that the quoted budget aligns with the engineering reality.

2. The Ordering Phase

The PO has been cut. The clock starts ticking on lead times.

The Reality: Supply chain volatility is the new normal. A "2-week lead time" can silently turn into 12 weeks.

The Goal: Vendor accountability. You need to know not just that it was ordered, but when it is promised, so you can schedule your panel builders accordingly.

3. The Received Phase

The box has arrived at the receiving dock.

The Reality: Boxes get piled up. If a part isn't immediately checked against the packing slip and the PO, you risk paying for damaged or incorrect goods.

The Goal: Verification. This is the physical handshake between your bank account and your inventory.

4. The Staged Phase

The part is moved from general inventory to a project-specific bin or pallet.

The Reality: This is the "Black Hole" of integration. Parts are often "borrowed" for other hot projects without documentation.

The Goal: Allocation. Once a part is staged, it is mathematically "consumed" by the project, preventing duplicate purchasing.

5. The Installed Phase

The component is mounted on the DIN rail or backplane.

The Reality: Just because it’s in the panel doesn’t mean it works. Installation is the precursor to power-up and commissioning.

The Goal: Progress validation. An installed part is a tangible metric of project completion.

The Financial Lens: Why Your CFO Cares

As an engineer, you care about the part being available. But your accountant (and your business owner) cares about what that part represents on the balance sheet.

Distinctly tracking these phases solves three major accounting headaches:

1. Managing Work in Progress (WIP)

The Problem: If you have $50,000 worth of hardware sitting on a shelf, is that an expense or an asset?

The Fix:

Received/Staged: This is essentially inventory asset. It has value, but it hasn't generated revenue yet.

Installed: This moves the needle on Percent Complete. In fixed-bid contracts, you often cannot recognize revenue until you can prove progress. accurately tracking "Installed" status allows you to defensibly claim a higher % complete, allowing you to invoice the client sooner.

2. Accurate Cost of Goods Sold (COGS)

The Problem: "Job Costing" is impossible if you don't know when a part was actually used. If a part is ordered in January but not installed until March, hitting the P&L in January skews your monthly profitability reports.

The Fix: By tracking the transition from Staged to Installed, you ensure that the cost of the hardware hits your books in the same period you recognize the revenue for the work. This is the "Matching Principle" of accounting, and it is vital for understanding if a project is actually making money.

3. Cash Flow Management

The Problem: Buying parts too early ties up cash; buying them too late delays milestones (and payment).

The Fix: By analyzing the delta between Ordering and Received, you can optimize your "Just-in-Time" purchasing. You stop acting as a free storage unit for your vendors and keep cash in the business until it is absolutely necessary to spend it.

Stop Guessing, Start Tracking

In the world of systems integration, hardware isn't just metal and silicon—it's capital. When you treat your material tracking with the same rigor as your PLC logic, you stop bleeding margin and start building a more predictable, profitable business.

Time Assign isn't just about tracking hours; it's about tracking the pulse of your projects. By integrating material status directly into your project management workflow, you give your engineers the tools to build faster and your accountants the data to forecast better.