The Digital Heartbeat of Automation

3 mins read

Published Feb 4, 2026

In the world of industrial systems integration, data is the most valuable currency. For years, the 4-20mA current loop has been the "gold standard" for transmitting process variables like temperature, pressure, and flow. However, standard analog signals are limited; they can only tell you what the measurement is, not how the sensor is feeling.

At Time Assign, we help engineers bridge this gap. By utilizing the HART (Highway Addressable Remote Transducer) protocol, you can extract a wealth of diagnostic data from your field devices without running a single new wire.

How HART 4-20mA Signals Work

HART is often described as a "hybrid" protocol because it combines the reliability of traditional analog with the intelligence of digital communication.

The Analog Layer: The primary measurement (PV) still travels as a standard 4-20mA DC current. This ensures compatibility with legacy systems and safety-critical loops.

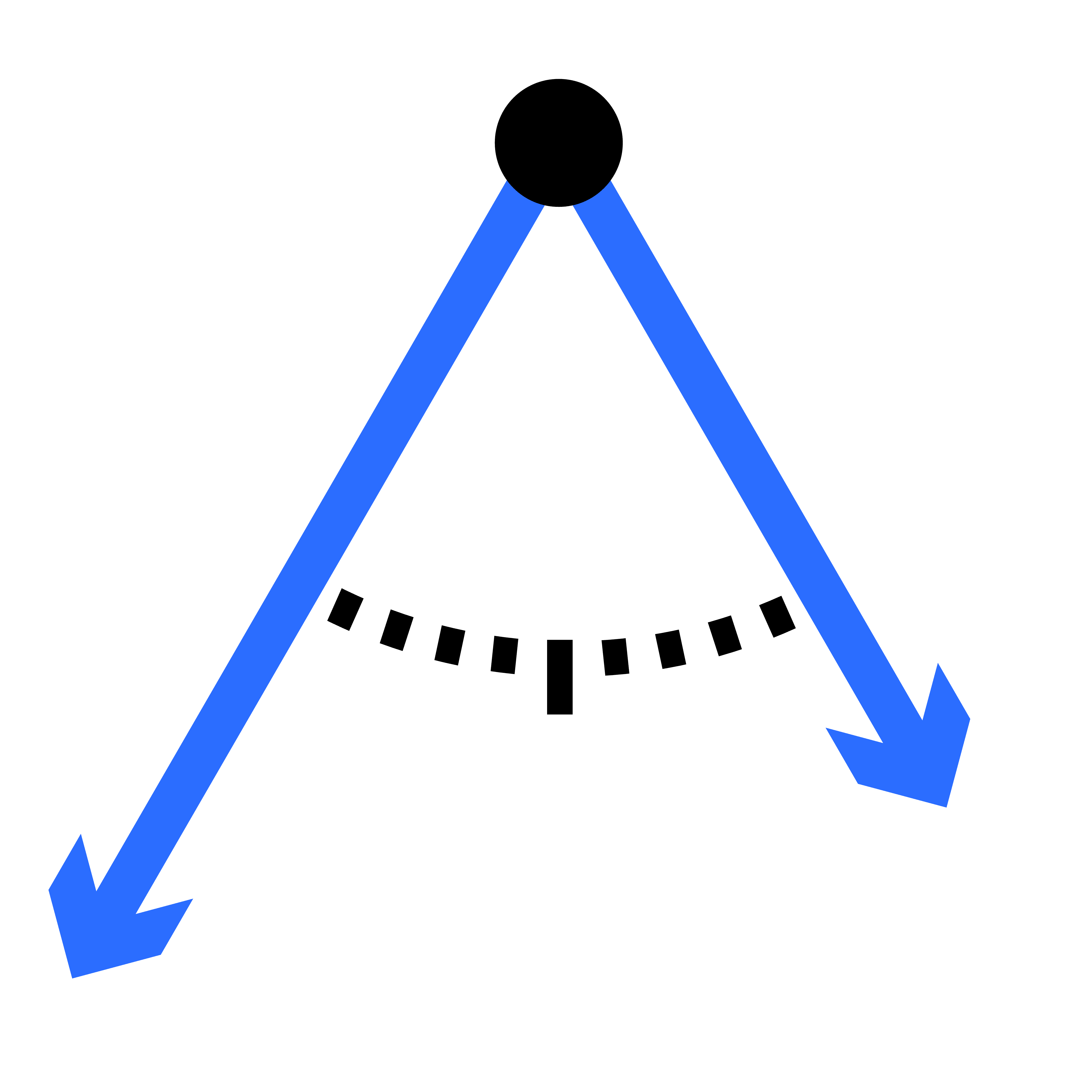

The Digital Layer: HART uses Frequency Shift Keying (FSK) to superimpose a digital signal on top of the analog current. It uses two specific frequencies:

1,200 Hz represents a binary "1".

2,200 Hz represents a binary "0".

See above image to see shift from 1,200 Hz to 2,200 Hz

Because the average value of these high-frequency sine waves is zero, they do not interfere with the DC 4-20mA signal. Your PLC sees the steady current for control, while your maintenance tools "listen" to the digital chatter for diagnostics.

Signal Showdown: HART vs. 4-20mA vs. 0-10V

Choosing the right signal depends on your environment and the level of detail your project requires.

Feature | 0-10V Signal | Standard 4-20mA | HART 4-20mA |

Noise Immunity | Low (Voltage sags/EMI) | High | High |

Distance | Short (Max ~15m) | Long (Up to 1km+) | Long (Up to 1km+) |

Fault Detection | Poor (0V = 0% or Fail?) | Good ("Live Zero" at 4mA) | Excellent (Digital Error Codes) |

Data Capacity | 1 Variable | 1 Variable | Multiple Variables + Health |

Configuration | Manual (Pots/Jumpers) | Manual (Pots/Jumpers) | Remote/Digital |

Why 0-10V is fading: While cheap and easy to test with a basic multimeter, voltage signals are susceptible to ground loops and electrical noise from motors or VFDs. In a systems integration environment, 4-20mA is preferred for its "live zero" (if the wire breaks, current hits 0mA, triggering an instant alarm).

What Can You Configure and Monitor?

The real power of HART lies in its ability to let you "talk" to the instrument. Beyond the primary variable, you can access:

Device Identification: Manufacturer ID, device type, and unique Tag numbers.

Configuration: Remotely change the Range (e.g., re-scaling a 0-100 PSI sensor to 0-50 PSI) or adjust Damping times.

Secondary Variables: A single HART flow meter can transmit flow rate (Primary), totalized flow (Secondary), and even fluid temperature (Tertiary) over the same two wires.

Calibration & Trim: Perform "Sensor Trims" and "Output Trims" to align the digital sensor readings with the actual loop current.

Interacting with the Loop: Handhelds vs. PLCs

To unlock these features, you need a "Master" device to communicate with the "Slave" field instrument.

1. Dedicated Handheld Communicators

Devices like the Emerson Trex or the classic HART 475 are essential for field troubleshooting.

How they work: You clip the leads across the 4-20mA terminals (or across a 250-ohm resistor).

When to use: Ideal for commissioning a new instrument on the bench or troubleshooting a "failed" sensor in the field without heading back to the control room.

2. HART-Enabled PLC Cards

Most modern PLC platforms (like Allen-Bradley ControlLogix or Siemens S7-1500) offer dedicated HART I/O modules,

The Advantage: These cards act as a permanent bridge. You can monitor device health directly in your SCADA or HMI code. If a sensor starts to drift or detects an internal failure, the PLC can trigger a maintenance alert before the process actually fails.

Asset Management: Using "Pass-Through" technology, software on your PC can reach through the PLC to configure the field device as if you were standing right next to it with a handheld.

Next Steps for Your Project

Integrating HART into your control system reduces "blind spots" and slashes troubleshooting time.