The Art of the Submittal

3 mins read

Published Jan 26, 2026

In the world of systems integration and control engineering, the "submittal" is often viewed as just another bureaucratic hurdle—a stack of PDFs standing between you and the actual work.

But experienced engineers know the truth: The submittal is your first line of defense.

A well-executed submittal package doesn't just get you approval to order parts; it protects your timeline, safeguards your budget, and sets the tone for the entire project. At Time Assign, we help integrators manage the hours that go into these critical tasks. Here is what you need to know to master the submittal process.

What Exactly is a Submittal?

In the context of industrial automation and construction, a submittal is a collection of documents provided by the contractor (or systems integrator) to the architect or engineer of record for approval.

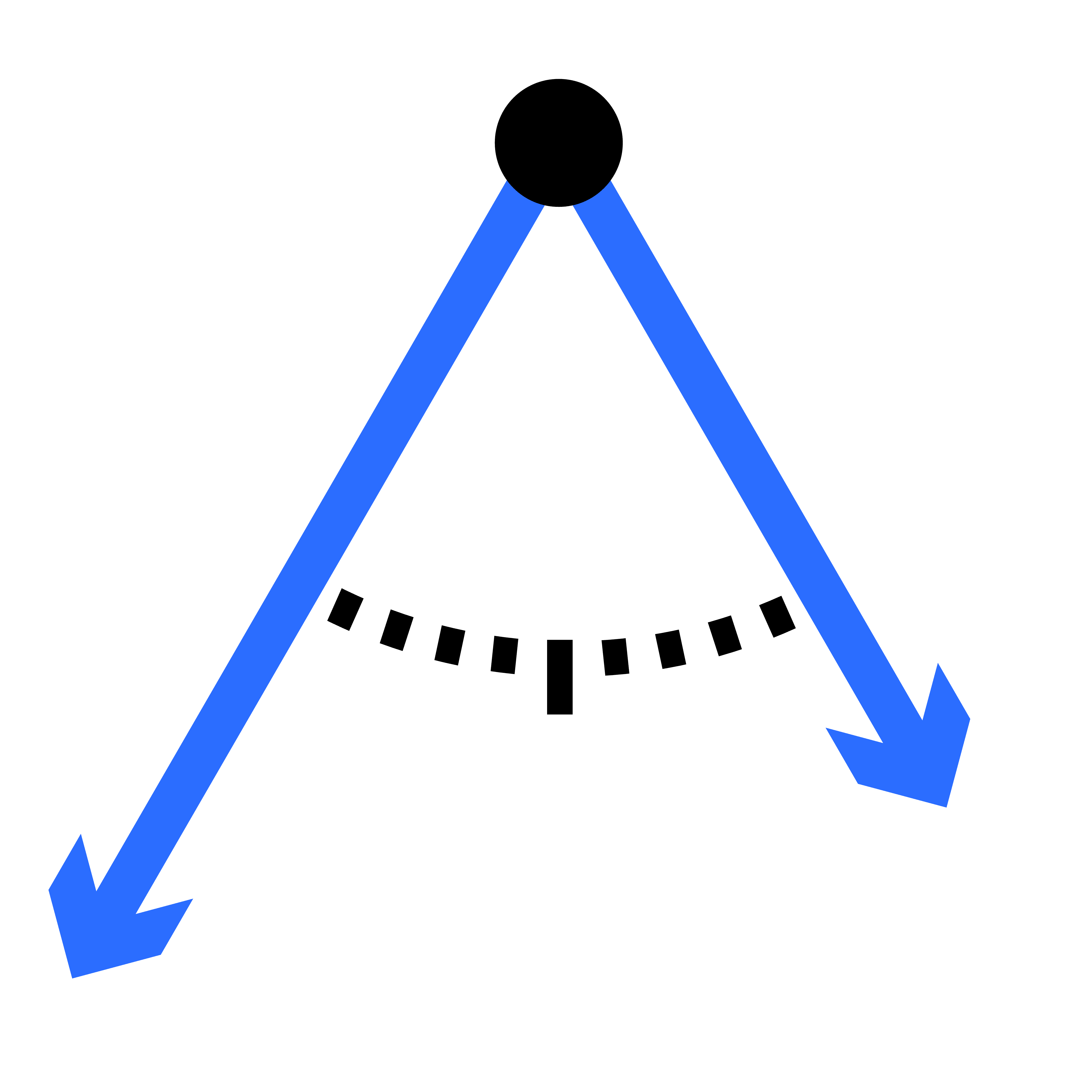

It serves as the bridge between the high-level design concepts in the bid documents and the physical reality of what you intend to build. It confirms, "We understand the requirements, and here is exactly what we plan to provide."

Common components of a controls submittal include:

Product Data (Cut Sheets): Manufacturer specifications for sensors, PLCs, and panels.

Shop Drawings: Wiring diagrams, panel layouts, and network architectures.

Samples: Physical examples of finishes or components (less common in controls, but applicable).

Certificates of Compliance: Proof that components meet UL, CE, or other standards.

What Makes a "Good" Submittal?

A bad submittal results in the dreaded "Revise and Resubmit" (R&R) status. This kills project momentum and burns billable engineering hours that weren't budgeted.

A good submittal is designed to make the reviewer’s job easy. It should be:

1. Organized and Navigable

Don't send a 500-page unsearchable PDF. Use bookmarks, a clear Table of Contents, and logical sectioning (e.g., Section 1: Field Devices, Section 2: Control Panels, Section 3: Software).

2. Clean and Highlighted

Reviewers hate guessing which part number applies to them. If a datasheet covers 20 different models of a flow meter, highlight the specific model you are providing. A yellow highlight box over the exact part number shows attention to detail and reduces confusion.

3. Pre-Vetted

Never copy-paste a generic list. Ensure every component actually fits the application constraints (voltage, environmental rating, communication protocol) before it goes into the package.

The Critical Importance of Specification Callouts

This is the area where most submittals fail. It is not enough to simply provide a datasheet; you must prove that your choice meets the project's Specification Sections.

When a reviewer looks at your submittal, they are comparing it against a specific section of the project manual (e.g., Division 25 - Integrated Automation).

Why "Exact Callouts" Matter

If the project specification requires a pressure transmitter with “+/- 0.5% accuracy and Hart communication,” your submittal needs to explicitly show that your selected device meets those two points.

Best Practice: Include a "Compliance Matrix" or add annotations directly on your cut sheets that reference the specification paragraph.

Example Annotation: “Referencing Spec Section 25 10 00, Para 2.3.A: Selected model 3051S provides 0.04% accuracy, exceeding the 0.5% requirement.”

The Risk of Being Vague

If you leave it up to the reviewer to find the accuracy rating buried in a 40-page datasheet, two things happen:

Rejection Risk: They may miss it and reject the submittal, costing you time.

Liability Risk: If you supply a part that doesn't meet spec, and you didn't call it out, you are on the hook to replace it later—at your own cost.

Managing the Time Cost of Submittals

Creating a bulletproof submittal takes time—time that is often underestimated during the bidding phase.

Reviewing Specs: 2–4 hours

Gathering Cut Sheets: 2–3 hours

Drafting Shop Drawings: 10–40+ hours

Revisions: Variable

If you aren't tracking the time your engineers spend on the submittal phase, you are likely bleeding profit before the panels are even built.

Time Assign helps systems integrators track these specific project phases, giving you the data you need to bid more accurately on the next job. Don’t let administrative work eat into your engineering margins—track it, manage it, and get your submittals approved on the first pass.