The Industrial Rosetta Stone

5 mins read

Published Jan 17, 2026

For a controls engineer or system integrator, the plant floor can feel like the Tower of Babel. You have a legacy chiller speaking Modbus, a new conveyor system shouting in EtherNet/IP, and a frantic IT department demanding data via MQTT.

Successfully navigating this ecosystem isn't just about getting devices to talk—it’s about choosing the right language for the right task to avoid latency issues, security gaps, and integration nightmares.

At Time Assign, we know that half the battle in system integration is managing the scope of these complex communication architectures. Below, we compare the industry heavyweights to help you decide which protocol belongs in your next project.

1. Modbus TCP/IP: The Universal Translator

The "Old Reliable"

If there is a lingua franca of industrial automation, it is Modbus. Originally developed in 1979, the TCP/IP variant wraps the simple serial protocol in an Ethernet packet.

How it works: It uses a Master/Slave (Client/Server) architecture. The Client asks for a specific register (e.g., Address 40001), and the Server responds with the raw data.

Pros: Universally supported (from $20 temperature sensors to million-dollar turbines), free to implement, and incredibly simple to troubleshoot.

Cons: It’s "dumb" data—address 40001 could be a temperature or a fault code; the protocol doesn't tell you. It also lacks inherent security (no encryption/authentication).

Best Use Case: Polling simple data from legacy equipment or low-cost sensors where high speed and security are not critical.

2. EtherNet/IP & Profinet: The Real-Time Rivals

The Heavy Hitters

These are the standard-bearers for real-time I/O control. While they occupy similar spaces, they are often divided by geography and PLC manufacturer preference.

EtherNet/IP (EIP)

Ecosystem: Predominantly Rockwell Automation (Allen-Bradley) and North American markets.

How it works: Uses the Common Industrial Protocol (CIP). It treats data as "Objects" rather than flat registers. It relies on UDP for fast I/O messaging and TCP for configuration.

Best Use Case: High-speed communication between PLCs, VFDs, and Remote I/O in a Rockwell environment.

Profinet

Ecosystem: Predominantly Siemens and European markets.

How it works: Offers different classes (Conformance Classes). Profinet IRT (Isochronous Real-Time) bypasses the standard TCP/IP stack to achieve sub-millisecond synchronization for motion control.

Best Use Case: Precision motion control and high-speed manufacturing lines, especially within the Siemens ecosystem.

3. OPC UA: The Modern Bridge

The IT/OT Unifier

Open Platform Communications Unified Architecture (OPC UA) is less of a "driver" and more of a platform-independent service-oriented architecture. It is rapidly becoming the standard for Industry 4.0.

How it works: Unlike Modbus, OPC UA is semantically rich. When you read a tag, you get the value, the data type, the timestamp, and the quality status all at once. It also includes built-in security (certificates, encryption).

Pros: Vendor-neutral, secure by design, and easily traverses firewalls.

Cons: Higher overhead; it requires more processing power and bandwidth than a simple Modbus poll.

Best Use Case: Connecting the plant floor (OT) to top-floor systems (SCADA, MES, ERP) or securely bridging two different PLC brands.

4. MQTT: The IoT Connector

The Lightweight Contender

Originally built for monitoring oil pipelines over patchy satellite connections, MQTT has found a new home in the Industrial Internet of Things (IIoT).

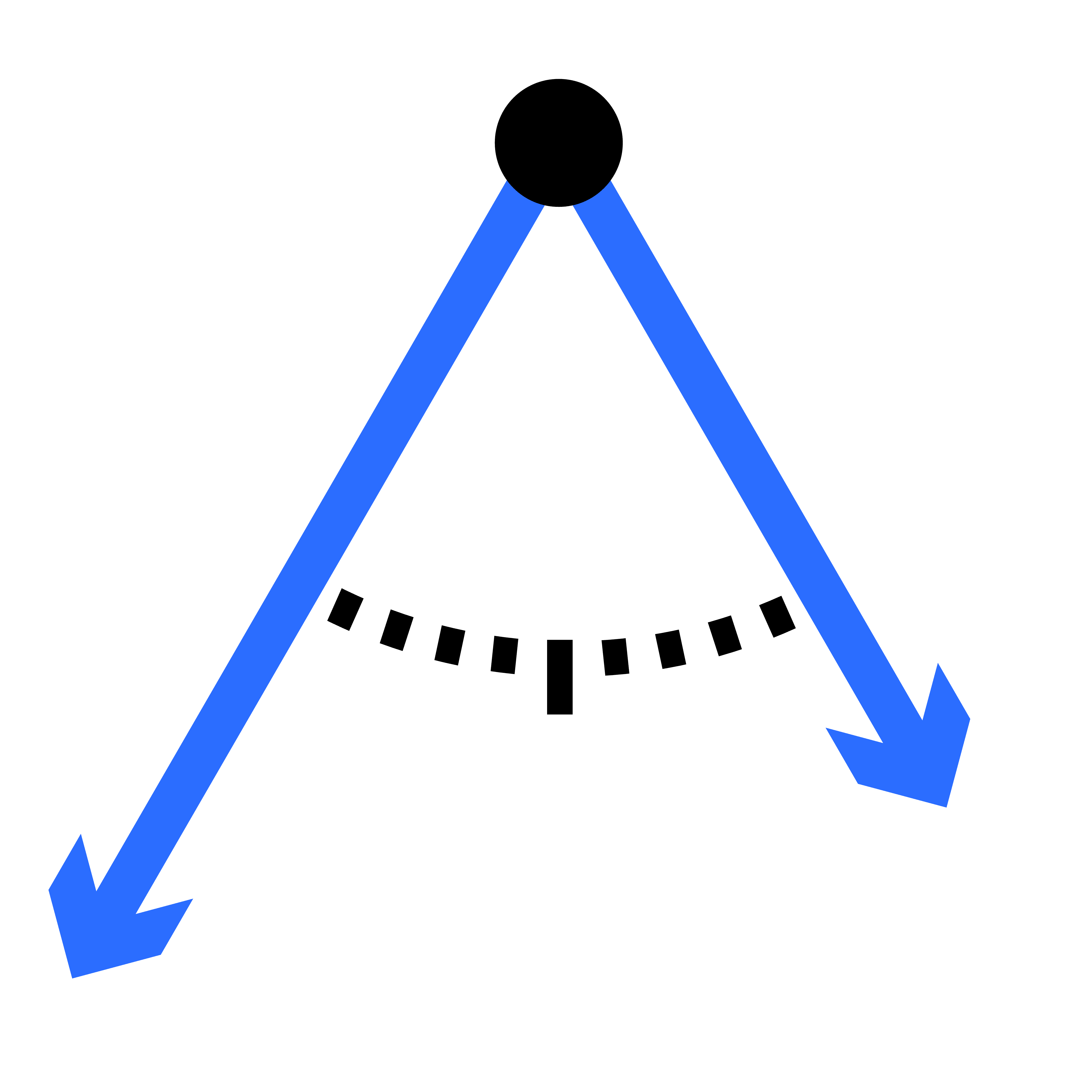

How it works: It uses a Publish/Subscribe model. Devices "publish" data to a central Broker, and other clients "subscribe" to that data. The device doesn't need to know who is listening.

Pros: Extremely lightweight and bandwidth-efficient. Great for intermittent networks.

Cons: Not deterministic—you would never use MQTT to control a robotic arm in real-time.

Best Use Case: Sending non-critical telemetry data from edge devices to the Cloud for logging and analytics.

The Hidden Cost of Integration

Technical capability is only one part of the equation. The other is implementation time.

Integrating a brownfield plant that requires mapping 500 Modbus registers, setting up an OPC UA server for the MES, and configuring Profinet safety zones is a massive undertaking. These projects are notorious for scope creep—what looks like a simple "data handoff" can turn into weeks of debugging register offsets and firewall rules.

How Time Assign Helps

When you are juggling multiple protocols, you need to know exactly where your engineering hours are going. Time Assign is built specifically for controls engineers and system integrators to:

Track specific tasks: Log hours separately for "Modbus Troubleshooting" vs. "HMI Development."

Manage Scope: See instantly when a "simple integration" project goes over budget due to protocol complexity.

Billing Accuracy: Ensure you are paid for the high-value expertise required to make OPC UA talk to a 30-year-old PLC.

Don't let the complexity of industrial protocols eat into your margins. Start tracking your engineering time effectively with Time Assign.